Streamline Manufacturing Process with Odoo 16

The modern manufacturing sector is a highly competitive and fast-paced environment that requires close orchestration of operations, resources, and timelines for success. The difficulties of managing such processes can be daunting, yet Odoo 16 ERP system offers an effective solution. This blog post will explore how Odoo 16 is revolutionizing the way companies manage their manufacturing processes, leading to improved efficiency, reduced costs, and better product quality.

We can explore how Odoo 16 can manage the manufacturing process. This Odoo Manufacturing ERP module is both easy to use and sophisticated, allowing for detailed orchestration and tracking of Odoo manufacturing operations.

It offers features such as the configuration of work centers, crafting Bills of Materials, creating manufacturing orders, monitoring progress, and managing component availability. Moreover, it provides detailed reports and analysis, so data-driven decisions for improved efficiency can be made.

Join us as we dive into Odoo 16’s Manufacturing module to learn more about its features, advantages, and practical use cases for bringing manufacturing to the next level.

Grasping the Functionality of Work Centers in Odoo 16:

Odoo 16 provides a robust suite of tools to facilitate the organization of manufacturing operations, with “Work Centers” forming a crucial component. These work centers are the dedicated sites at which various procedures are carried out in the production of the final product. Accessing and configuring a Work Center in Odoo 16 is simple and efficient. The following steps will help you create and manage Work Centers successfully.

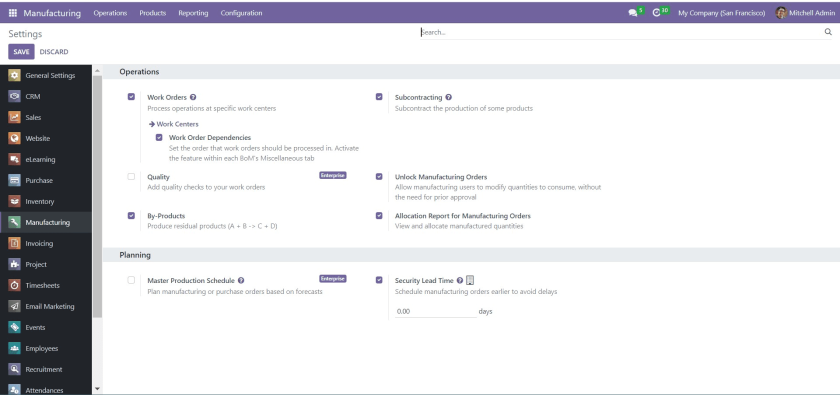

- Begin by accessing the “Configuration” menu.

- Inside the Configuration options, you’ll find the choice to ” Activate Work Orders.” Enable this option to get the work order feature operational.

The dashboard allows for a quick and easy view of the work centers you have set up upon the activation of work orders.

Once enabled, you can quickly access and monitor these work centers.

Establishing Fresh Work Places:

- To begin, go to the “Configuration” area. In the Configuration options, look for and select “Work Centers.”

- Once you are in the Work Centers portion of the application, you will be able to start designing your own work center by clicking the “Create” button. Additionally, you will be able to view images of the process with the accompanying screenshots.

1. Essential Details: To get started, supply the key specifics about your work center:

- Give your work center a title that describes it accurately to make it easily identifiable.

- Assign an individual code to facilitate tracking and management.

- Utilize an appropriate tag to systematize and organize your work centers proficiently.

2. Achieving Seamless Production: Planning for a second work center is a great way to guarantee that there will be no disruption to manufacturing operations. This kind of contingency measure will ensure that the production process will keep running even when the main work center is busy.

3. Efficiency in terms of Time and Capacity:

- Clearly outline the Length of Time that operations at the work center will take so that scheduling can be done accordingly.

- Indicate the Maximum Volume that can be produced by the work center within a given period.

4. Enhancing Performance:

- Establish a Goal for Overall Equipment Efficiency with the purpose of maximizing productivity and minimizing non-productive time.

- Calculate the Time Needed Prior to and After Production , incorporating setup and post-production tasks connected to manufacturing operations.

The world of technology today is a fast-paced one; advancements and innovations occur at an almost dizzying rate. It can be hard to keep up with the latest trends and gadgets, but it is important to stay up to date and informed. Keeping an eye on the latest developments in technology is essential in order to remain competitive and to take advantage of the incredible possibilities that technology offers.

The effects of climate change are becoming increasingly evident, with temperatures rising and extreme weather events becoming more regular. One example of this is the melting of the polar ice caps, which is leading to rising sea levels. Additionally, changes in the climate are affecting ecosystems and the natural world, as species struggle to adapt to new conditions.

5. Equipment & Connectivity: In the Equipment section, make sure your work center is outfitted optimally for maximal productivity.

- Make sure that your work environment is outfitted with the right Tools and Supplies.

- Check the IoT Triggers menu to pick out the devices that will allow for better connectivity and real-time tracking.

The use of technology in today’s day and age has become an integral part of life. It has become commonplace to incorporate tech into daily routines, from managing finances to communicating with friends and family. With the ubiquity of technology, it is no surprise that it has drastically changed the way we live.

The use of technology in education is becoming increasingly prevalent, as more and more schools and universities adopt digital learning tools. This phenomenon is having a major impact on the way students learn, making the educational experience much more dynamic and interactive. Nowadays, technology is playing a significant role in the classroom, allowing educators to engage with their students in unique and engaging ways.

6. Preserving Your Configuration: Once you’ve finished adding and optimizing your details, it’s important to remember to save your changes:

- Utilize the “Save” button to compile your information and make your carefully created work center become a reality.

It is evident that the utilization of technology has become increasingly significant in our everyday lives. Nowadays, it is not uncommon to find people using technological devices in a variety of ways, from communication to entertainment and more. The reliance on technology has come to be a major part of the modern experience.

The amount of time students spend on their electronic devices has increased drastically in recent years. Nowadays, it is not uncommon for young people to spend large portions of their day on their phones, tablets, or computers. This has resulted in a decrease in physical activity and a rise in sedentary behaviour.

Odoo 16 presents a powerful set of tools for managing work centers that allow producers to make the best use of resources, streamline production sequences, and upgrade general efficiency in manufacturing. The broad range of functionalities supplied by Odoo 16 guarantee that your Odoo manufacturing procedures are kept neatly organized and supervised for peak performance.

List of Elements in the Product (BoM)

The Bill of Materials plays an indispensable part in the manufacturing cycle, as it outlines the components, materials, and operations needed to produce the final product. This document is essential to the production process, providing guidance, preventing errors, and optimizing resources. Odoo 16 takes BoM development to an entirely new level, making it easier than ever before.

- Beginning the BoM Setup Process: The process begins by determining both the final product and the materials needed to build it. Prior to configuring the BoM, it is essential to comprehend the end product and its components.

- Accessing BoM Setup: To begin designing the BoM:

- To access the Bill of Materials, go to Products in the menu.

- Then, select the Bill of Materials option.

An image of a Odoo manufacturing process being managed with Odoo version 16.5 is presented. This ERP software solution helps to ensure that production is carried out efficiently and productively.

3. Press the ” New ” button to begin forming your BoM.

A helpful way to handle the production process with Odoo 16 is to utilize the 6 step approach. This entails the following:

- Establishing the production order

- Scheduling the production process

- Allocating the materials

- Executing the production process

- Verifying the quality of the product

- Wrapping up the production order

By using this method, Odoo 16 is able to assist in the successful management of the manufacturing process.

When creating a BoM, the product name should be given primary consideration. Therefore, enter the name of the item for which the BoM is being put together.

A picture can be seen here illustrating how to handle a manufacturing process with Odoo 16.7. This graphic provides an overview of the steps necessary to manage this kind of process effectively.

5. Putting Together Parts: The “Components” area is the spot where the real work is done:

- Dive into the Components tab.

- Make sure to list out all the necessary items or materials to create the end product.

The cost of living has increased significantly in recent years. This has been reflected in the rising prices of a variety of goods and services. It is a trend that has affected many households and has made budgeting more essential than ever.

Paraphrased:

Recently, the cost of living has undergone a significant hike, manifesting itself in higher prices for various products and services. This has had a major impact on households, making budgeting an essential element of life.

6. Adding a Refined Manufacturing Process: To give a more detailed look, think about including work stations or routing specifics:

- For work centers or routing involved in the manufacturing process, go to the Operations tab.

- Enter the details here in order to have a comprehensive BoM.

7. Securing Your Creation: To protect the result of your hard work, make sure your BoM is kept safe:

- Make sure to click the “Save” button in order to confirm the Bill of Materials created with care.

The use of augmented reality (AR) in the classroom has the potential to revolutionize the way students learn. It can be used to increase engagement and knowledge retention by allowing students to visualize concepts and engage with them in a more interactive way. By utilizing AR, teachers can create an environment that promotes creativity and exploration, allowing students to explore and discover new ideas. Furthermore, AR can be used to provide students with real-time feedback on their progress, making learning more efficient and enjoyable.

The world is changing rapidly and technology is advancing at an unprecedented rate. Progress is being made in a variety of areas, from transportation to communication. As a result, what was once impossible has become possible due to the advent of modern technology. People are now able to access information, communicate with each other, and even travel to far-off places with relative ease. The advances in technology have enabled us to do things that were not feasible in the past. As such, the world is a much different place than it was even a few decades ago.

Once the BoM is generated, it can then be used to create manufacturing orders, keep tabs on progress, and ensure a smooth Odoo manufacturing process. With Odoo 16, crafting a BoM grants you the capability to manage production with accuracy and insight. Developing blueprints of this sort gives you the opportunity to traverse the complicated terrain of manufacturing with ease and anticipation.

The Creation of Manufactured Items

The process of manufacturing orders is a complex one. It involves a range of activities, from planning and costing to sourcing materials and managing production. Different steps must be taken in order to create a finished product, and all of these steps must be carefully monitored in order to ensure quality and meet customer expectations.

The Operations menu of Odoo 16 provides the ability to create Manufacturing Orders, which form the basis of the production process. These orders allow you to convey the requirements of your product into distinct tasks that can be followed by your team. In order to effectively handle the orders, here’s what you should do:

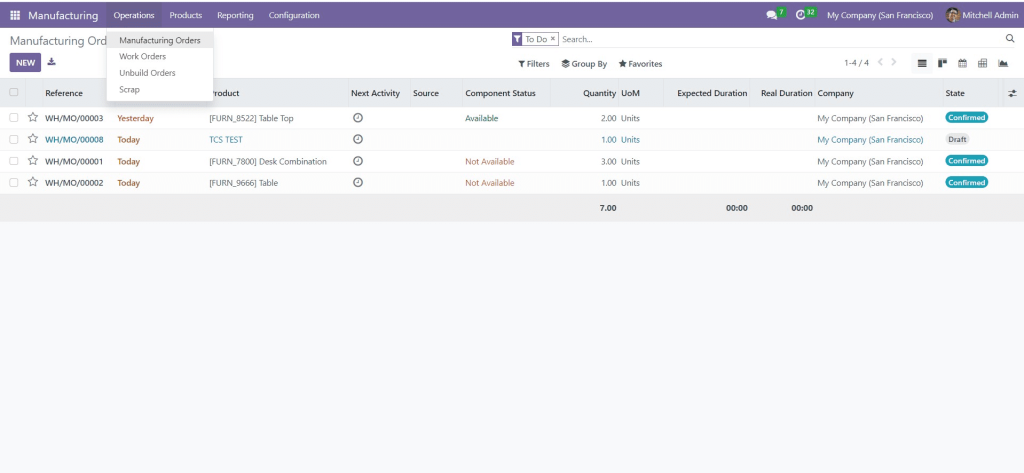

1. Accessing Manufacturing Orders:

- In order to start the procedure of generating manufacturing orders, access Operations > Manufacturing Orders.

- Upon your entrance, you will come across a compilation of existing fabrication orders.

In order to craft a new manufacturing order, one must simply locate the “New” button and click it.

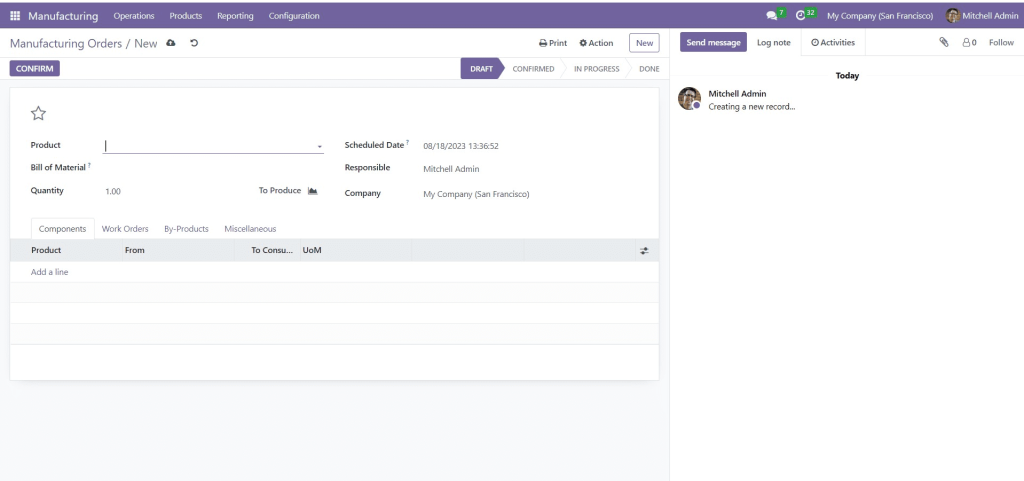

3. Establishing the Order:

- Begin by choosing the item you need to create a manufacturing order for.

- When the product is chosen, the linked parts will be filled in automatically, making the process easier.

- Adjust the logistics by selecting an appropriate Appointed Date and specifying the amount that must be manufactured.

- Identify the person responsible who will control the order placement.

- An illustration of the utilization of Odoo 16-11 to oversee manufacturing processes can be seen in the image above. It is an effective way to manage the production flow and keep track of the progress.

4. Verifying:

- When you are set to progress, press the Confirm button to validate the production order.

5. Taking Care of Component Accessibility:

- If any elements are not available or out of supply, the Component Status will be indicated as Not Available.

A picture of how to handle the production process with Odoo 16 can be seen here. This system helps to make it easier to manage the manufacturing process.

6. Steering Work Requests:

- Visiting the work orders menu is essential to plan the activities and work centers necessary to manufacture.

- You can choose between lingering for the part or deciding to scrap it.

- If waiting is not possible, creating a purchase order for the missing pieces is a seamless solution. When they arrive, these items will be available for use.

A diagram illustrating how to use Odoo Version 16-13 to administer manufacturing processes is depicted in the picture. An individual can use the software to organize and control the production flow.

7. Starting Production:

- Gather all the necessary elements and be ready to begin manufacturing.

- Just press the ” ** Begin** ” button to get the process going.

The results of the study showed that there was a significant difference between the two groups in terms of performance. It was evident that the experimental group had improved more than the control group, indicating that the intervention was successful.

The findings of the research indicated that there was a marked contrast between the two groups in terms of their performance. The experimental group exhibited greater enhancement than the control group, implying that the intervention had been successful.

The creation of a successful product demands a great deal of work. Making something successful necessitates putting in a lot of effort in order to achieve this goal. To maximize the chances of success, it is important to make sure that sufficient attention is paid to all of the necessary components. From research and planning, to design and delivery, every essential element needs to be taken into consideration. Doing so will help to ensure the highest likelihood of success.

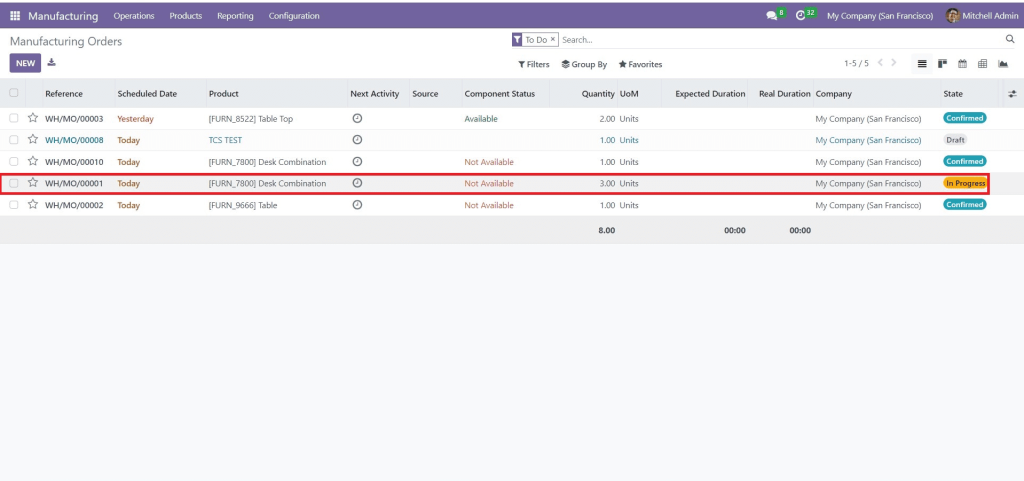

8. Advancement Phases:

- Monitor the progression of the manufacturing order as it shifts from “Confirmed” to “In Progress”.

Once operations are finished, pressing “Done” means that the stage has been completed. The “Mark as Done” button then appears to signify the concluding steps.

9. Finishing with Careful Consideration:

- When you click “Mark as Done”, a prompt will appear to confirm that the manufacturing process is finished.

- After that, the status will be switched from “To Close” to the last stage of “Done”.

10. Gaining a Deeper Understanding:

Investigating further into the processes of manufacturing can be done with the help of Odoo 16. By doing this, a more comprehensive grasp of the overall activity can be attained.

Gain thorough understanding by using convenient buttons that will take you to in-depth accounts of Traceability, Product Moves, and Cost Analysis.

A visual representation of how to handle the manufacturing process with Odoo 16 and 17 can be seen in the following image. It illustrates the steps taken to manage the process and the associated outcomes.

Taking advantage of Odoo Manufacturing can give you the ability to create manufacturing orders, progress them through the different phases of production, and reach the ultimate fulfillment of the production. Utilizing these simple and sequential steps can help you optimize your manufacturing effectiveness with Odoo 16, leading to smoother production and optimal performance.

Gains of Utilizing Odoo Manufacturing Administration

By taking advantage of Odoo Manufacturing Management, there are multiple benefits.

1. Improved Efficiency and Planning

Enhanced efficacy and organization can be achieved through improved efficiency and planning.

The Odoo Manufacturing Management system provides businesses with the opportunity to optimize their procedures. Automating duties, synchronizing work centers, and providing real-time team collaboration are just a few of the ways this ERP system eliminates delays and ensures steady operations. As a result, production cycles are faster, lead times are decreased, and productivity is improved.

2. Cost Reduction and Quality Enhancement

Costs can be cut, and quality can be improved through the implementation of certain strategies.

By keeping a close eye on resources, materials, and labor, Odoo can aid manufacturers in finding cost-saving opportunities. The system’s resource allocation optimization, minimization of wastage, and improved production planning can enable enterprises to reduce their operational costs. Furthermore, the emphasis on quality control allows for each product to meet specific standards, reducing the number of defects and the amount of rework needed. This dedication to quality leads to improved customer gratification and reinforces the brand’s standing.

The implementation of ERP for Manufacturing Management can drastically improve production procedures. It can help companies become more cost-effective and efficient, while simultaneously increasing the quality of their products, thereby allowing them to stay ahead of their rivals in the competitive marketplace.

In Summary

In conclusion, it can be seen that…

Odoo 16 offers an innovative Manufacturing Management module that facilitates a highly organized production process. With dynamic work centers, accurate Bills of Materials, efficient manufacturing orders, and reporting capabilities, the intuitive interface and powerful features of Odoo 16 lead to a streamlined manufacturing operation. This platform allows businesses to increase operational efficiency, reduce costs, and prioritize customer satisfaction. Therefore, businesses can leverage Odoo 16 to foster excellence in the manufacturing industry.

Our previous blog post on Odoo manufacturing provides an overview of the features in the Odoo 16 manufacturing module. Check it out to learn more.

The utilization of the Internet has increased significantly in the last few years. There has been a notable rise in people accessing the web for various reasons. From education and entertainment to information and communication, people have become highly reliant on the Internet for their day-to-day activities. Consequently, the reliance on the Internet has grown dramatically.

Rely on the Odooerp.ae for the development for ERP Software with best quality of service you have been searching for. You can contact for a free consultation and Book for a Demo